During these turbulent times, entrepreneurs need our support to continue driving their mission forward. While their long-term vision will benefit all of society, the short-term reality they are facing is brutal. The COVID-19 pandemic threatens up to one-third of US jobs, this is about 44 to 57 million individuals losing their financial lifeline. One third of these jobs are in small businesses that employ fewer than 100 people. While all businesses are searching for ways to continue their work, investment in early-stage ventures has fallen sharply. Global seed funding has dropped by 22% relative to Q4 of 2019, and it is projected to decline further (CB Insights, 2020).

The Straubel Foundation recognizes the challenges that this economic environment imposes on entrepreneurs and the talent they employ. To help mitigate these stressors, the Foundation will continue to search for and support ideas that are innovative, economically rigorous and of societal service. Through our Program Related Investments (PRIs), we express our commitment to the entrepreneurs’ long-term impact mission and the well-being of the people they employ.

Our Latest Investment: BioCellection

Recycling Unrecyclable Plastic

Today, less than 10% of plastic packaging gets recycled worldwide. The remaining 90% is sent to landfills, incinerators, and oceans. This means that about 360 million tons of non-biodegradable material is injected to our environment, annually. Of the seven types of packaging plastic, only two — PET and HDPE — are being recycled regularly on a commercial scale.

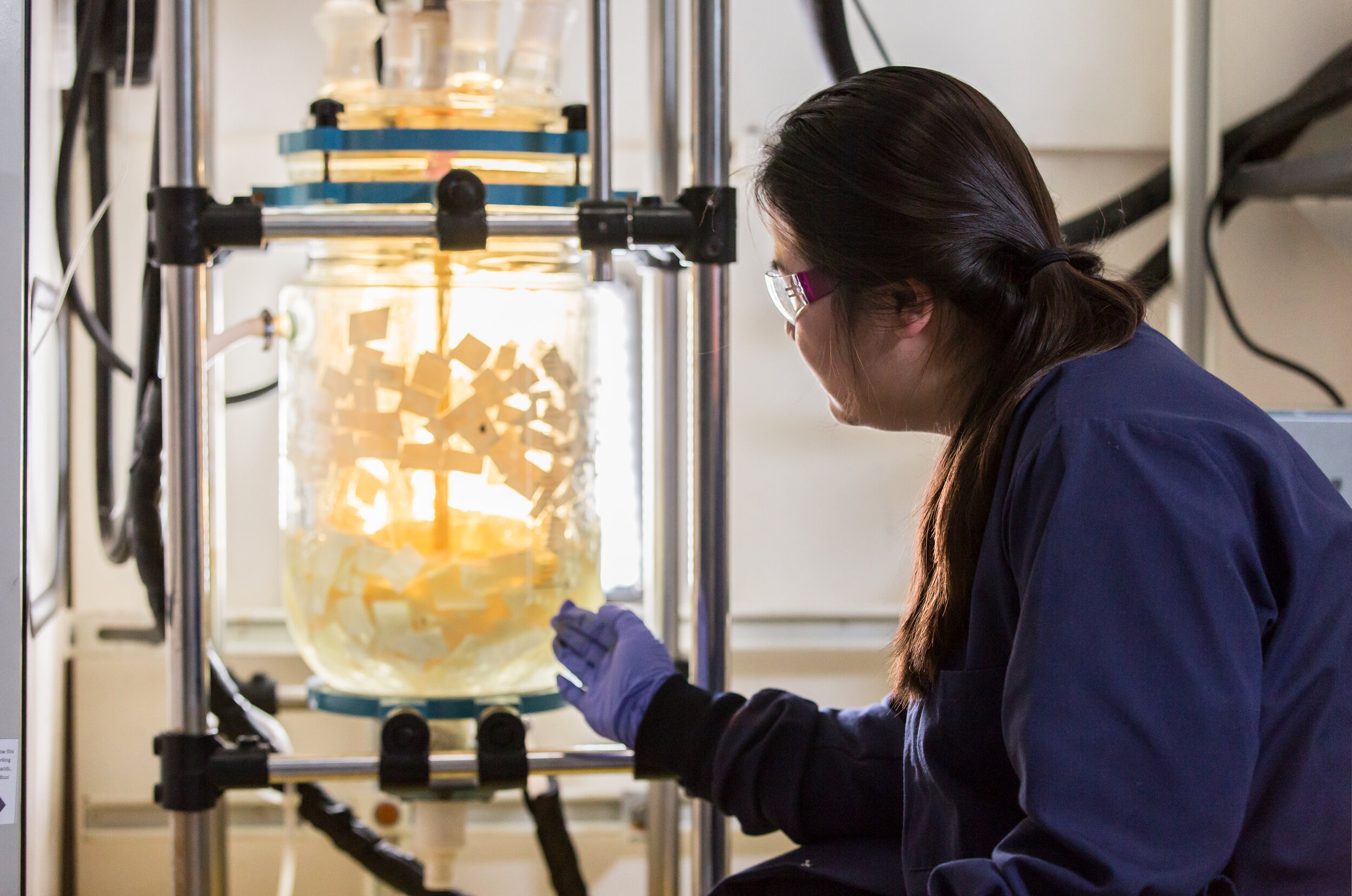

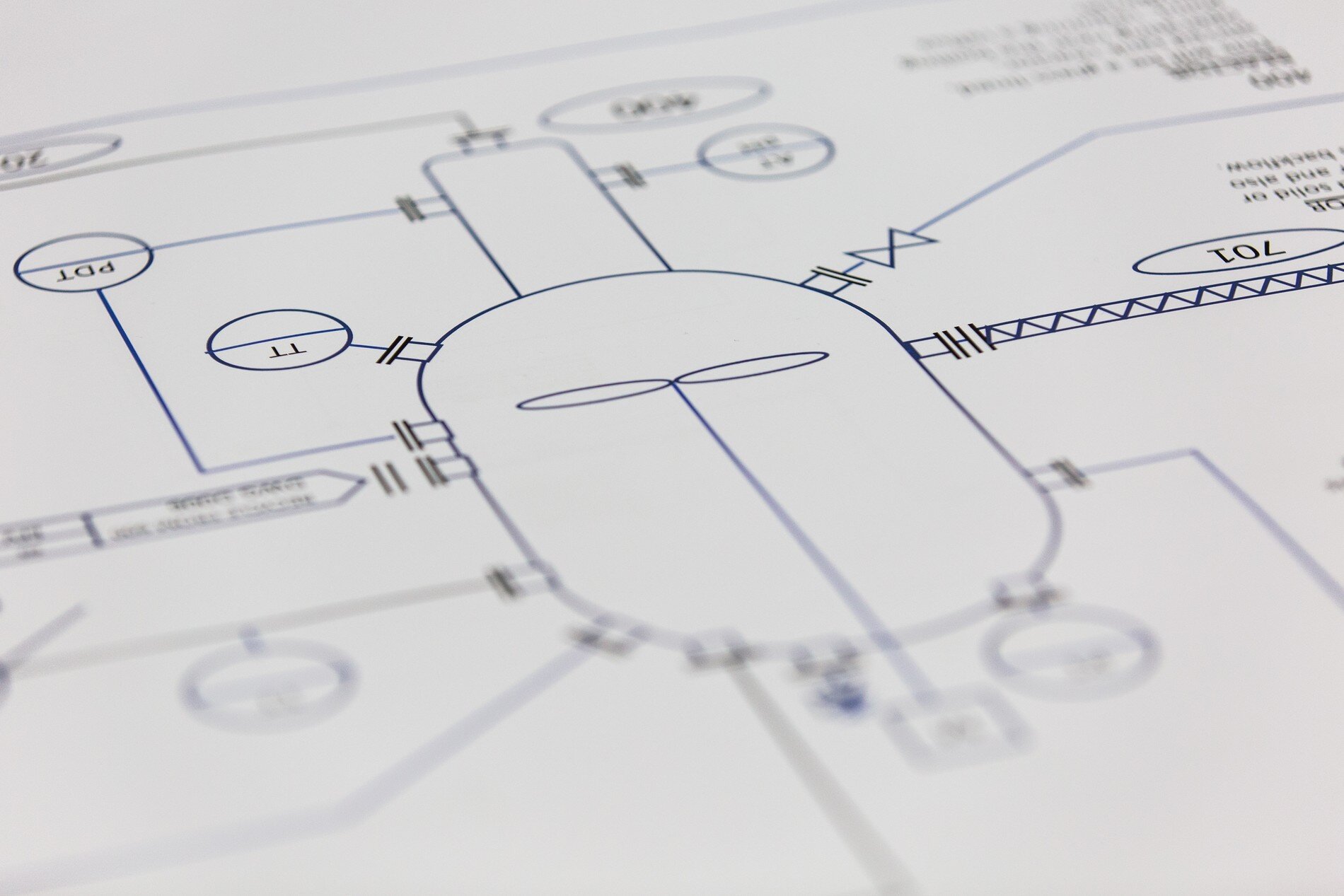

BioCellection is daring to innovate where traditional recycling is struggling. Starting with low grade plastic films, BioCellection aims to re-purpose plastics that constitute more than a third of plastics produced globally. LDPE and HDPE flexible plastics, think grocery bags, retail packaging, and food wraps, are the first to undergo BioCellection pioneering experimentation. ATOD™ (Accelerated Thermal Oxidative Decomposition) breaks polymers into lighter molecular components that can form useful organic acid compounds. These compounds, in turn, are chemical intermediates that can be used as building blocks for other valuable products, such as performance materials, solvents, coatings, compostables, and more. Virgin-grade thermoplastic polyurethane (TPU) used in outdoor apparel, cars, cables, and footwear is the first product BioCellection generated ready for commercialization. Many of these intermediates, such as succinic acid, glutaric acid, and adipic acid, are currently produced from petroleum. BioCellection ground-breaking innovation to extract these acids from post-consumer waste and upcycle them into performance materials will not only reduce the amount of plastic in our oceans and landfills, but will also lower our dependence on fossil fuels in supply chains.

JB Straubel pointed out that: "Materials recovery and re-use is one of the largest opportunities for global carbon mitigation and is often underappreciated. Plastics has been a difficult area to solve without subsidies. A deeper technical focus on improving the chemistry is a compelling idea for improving the economics and making plastic recycling a self-sustaining, positive business model."

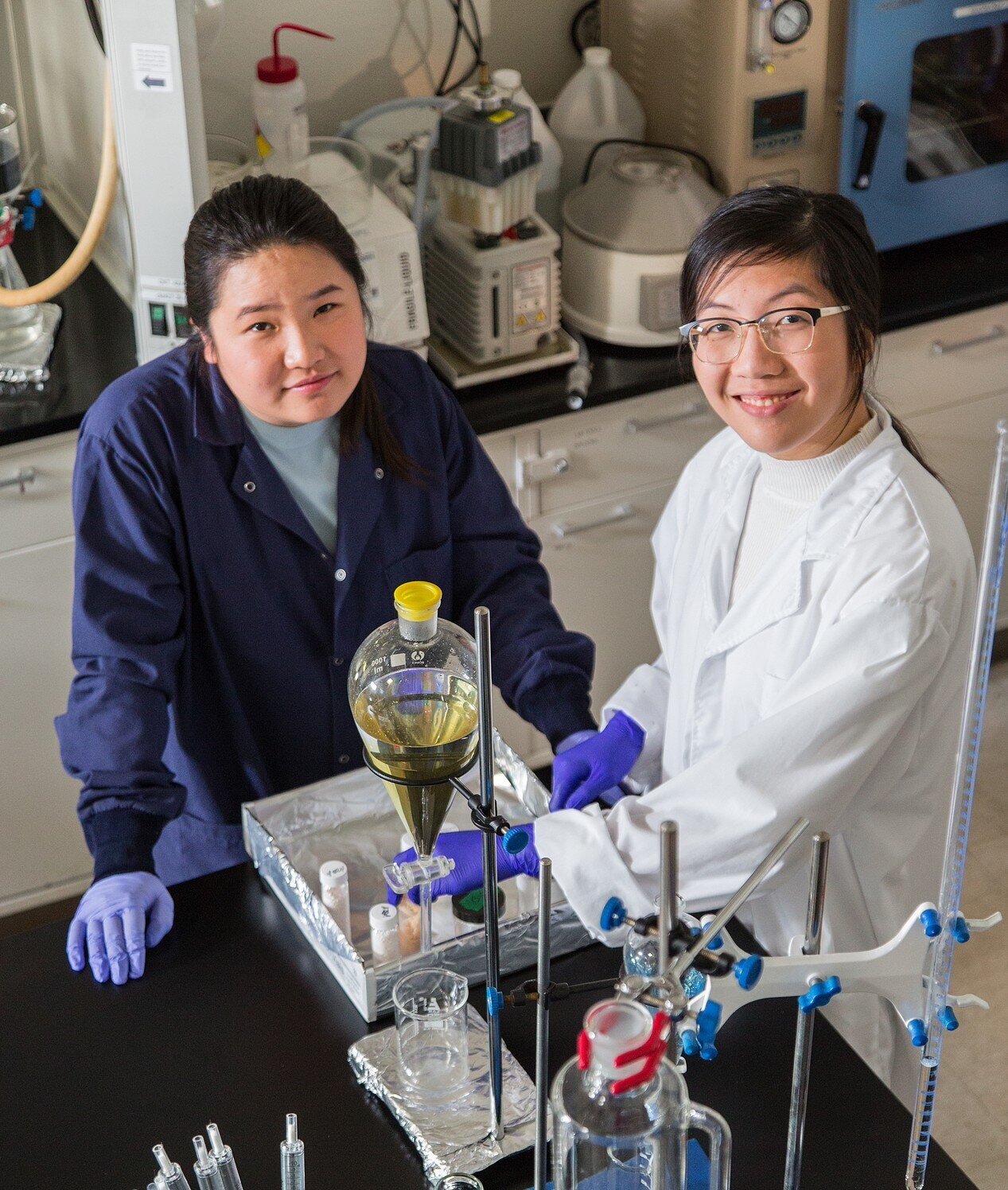

Jeanny Yao and Miranda Wang, co-founders of BioCellection, pledged their commitment to plastic upcycling when they were high schoolers visiting waste plants in Vancouver, Canada. Their determination to apply science to solve real-world problems became apparent at an early age. Dr. Lindsay Eltis, Canada Research Chair in Microbial Catabolism and Biocatalysis, who oversaw the work of Jeanny and Miranda in his lab at the University of British Columbia, remarked: “What really shone through for me was their rare passion for science”.

In 2015, at the age of 21, Jeanny and Miranda established BioCellection. In 2019, when named Straubel Impact Leaders, Forbes 30 Under 30, C&EN’s Trailblazers, and recipients of the MIT SOLVE Circular Economy award, the duo entrepreneurs were just beginning to share with the world the limitless ambition they have for upcycling plastics: “My dream is to lead our team to create the market-driven solutions that will keep our plastic molecules in use over and over; to show that a sad piece of plastic that no one believed we could use again can be turned into the highest performing material. We have proven that is possible. What’s left is to now scale it up and enable this innovation to change our world.” - Miranda Wang said.

“It takes all of us to create systemic change. In addition to building this technology, we look forward to collaborating with governments, industry players, and everyday consumers to scale this solution to global impact. ”- Jeanny Yao said

Visionary leadership is a quality that female entrepreneurs have in common. Today, more than a third of global businesses have women owners. Venture capital funding for firms with at least one female founder increased in value-per-deal by almost 2000% in the past decade (Goldman Sachs, 2019). Despite this increase, firms with women founders continue to lag behind all-men owned businesses in terms of accessing and securing credit. The proportion of dollar value of venture capital deals in firms with at least one female founder is no more than 19% for angel and seed stage, 15% for early stage, and 18.5% for late stage (Goldman Sachs, 2019). The disproportionate representation of women founders as recipients of investment funds is likely to be exacerbated by the current economic crisis arising from the COVID-19 pandemic.

Supporting and highlighting brilliant founders to the world is now an urgent and pressing need. “JB and I are excitedly investing in BioCellection. We see an important technological focus, driven by a rock star team. Jeanny and Miranda are unique: both are a rare combination of bold scientific brain power and personable entrepreneurial spirit.” — Boryana Straubel said.

Upcycling is key to making our economy circular, lands greener, and oceans cleaner. Let’s upcycle all garbage, one molecule at a time.

Image source: Rolex Awards For Enterprise